Our Placed Students

About Electrical Wiring Harness Course

The Electrical Wiring Harness Course at Caddesk Bangalore is designed to provide students with the knowledge and skills required to understand, design, and manage electrical wiring harness systems. Wiring harnesses are crucial components in the automotive, aerospace, and industrial sectors, ensuring the safe and efficient transmission of electrical power and signals throughout complex systems. This course equips students with both theoretical knowledge and hands-on experience in wiring harness design, development, and testing. During the Electrical Wiring Harness Course, students will be introduced to the fundamentals of wiring harnesses, including their components, types, and functions. They will learn how to design wiring systems that meet industry standards, and also gain practical knowledge of tools, techniques, and software used in the design process. The course covers the creation of electrical schematics, circuit layouts, and the management of wires, connectors, terminals, and other elements involved in the harness design. Additionally, students will explore topics like material selection, testing, quality control, and manufacturing processes. The Electrical Wiring Harness Course at Caddesk Bangalore is structured to ensure students develop the practical skills needed to succeed in the industry. They will have the opportunity to work with industry-standard software tools, simulate wiring systems, and apply their learning through practical exercises and case studies. The course is suitable for individuals aiming to pursue careers in electrical engineering, automotive design, or manufacturing, as well as for professionals looking to enhance their skills in the field of wiring harness design. With Caddesk Bangalore’s expert instructors guiding the course, students can expect high-quality training that blends theory with real-world applications. Whether you are looking to get started in the electrical design industry or further develop your existing knowledge, the Electrical Wiring Harness Course at Caddesk Bangalore will provide the necessary skills to advance your career in this critical engineering field. Best Electrical Wiring Harness course in Bangalore.

Electrical Wiring Harness Course Overview

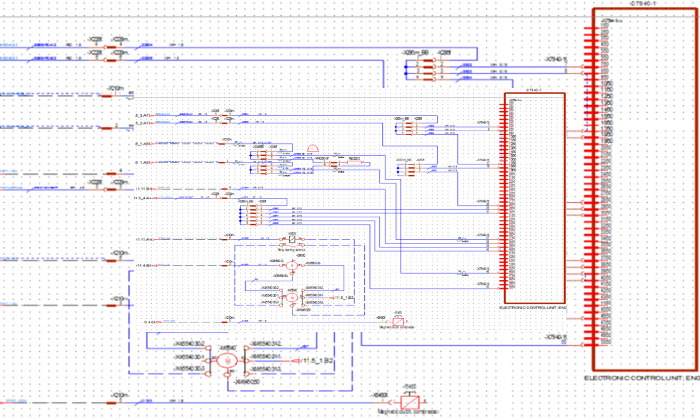

The Electrical Wiring Harness Course at Caddesk Bangalore provides comprehensive training on the design, development, and testing of wiring harnesses, which are crucial components in a wide range of industries such as automotive, aerospace, and industrial manufacturing. This course covers the entire lifecycle of electrical wiring harness systems, from basic principles to advanced design techniques, ensuring that students gain a deep understanding of this essential field. Throughout the course, students will explore the various types of wiring harnesses, their components, and how they are integrated into complex systems. The curriculum focuses on the practical aspects of designing wiring harnesses that meet industry standards for safety, performance, and efficiency. Topics such as electrical schematics, circuit layout, material selection, and the role of connectors, terminals, and insulation materials are thoroughly covered. Students will also learn how to manage the physical layout of wiring harnesses and create detailed documentation for manufacturing and assembly. The course introduces students to industry-standard software and tools used for wiring harness design, including CAD (Computer-Aided Design) software and specialized electrical wiring harness design tools. Through hands-on exercises and real-world case studies, students will gain practical experience in creating wiring harness layouts, validating designs, and performing tests to ensure the reliability and functionality of the harness systems. By the end of the Electrical Wiring Harness Course at Caddesk Bangalore, students will be equipped with the skills and knowledge necessary to design, manufacture, and test high-quality electrical wiring systems. This training is ideal for individuals seeking a career in electrical design, automotive engineering, or aerospace applications, as well as professionals looking to expand their skill set in the field of electrical systems integration and harness design. The course is structured to cater to learners at all levels, with both offline and online training options available, allowing flexibility for students with various schedules and learning preferences. Whether you’re just starting in the field or looking to upgrade your expertise, Caddesk Bangalore provides a thorough and practical education in electrical wiring harness design that is recognized by industry professionals. Best Electrical Wiring Harness course in Bangalore.

Electrical Wiring Harness Course Curriculum

- Overview of electrical wiring harnesses and their importance.

- Key components and their functions.

- Applications in various industries (automotive, aerospace, industrial)

- Fundamental electrical concepts: voltage, current, resistance, and power.

- Understanding circuits: series and parallel configurations.

- Safety practices in electrical work.

- Design considerations: layout, routing, and packaging.

- Material selection: wires, connectors, insulation types.

- Importance of wire gauge and color coding.

- Introduction to CAD software (e.g., AutoCAD, SolidWorks) for wiring harness design.

- Creating wiring diagrams and schematics.

- Developing 2D and 3D models of wiring harnesses.

- Overview of manufacturing techniques for wiring harnesses.

- Techniques for cutting, stripping, crimping, and soldering wires.

- Quality control processes in harness manufacturing.

- Testing methods for electrical wiring harnesses (continuity, insulation resistance, etc.).

- Tools and equipment used for testing (multimeters, oscilloscopes).

- Importance of validation in ensuring reliability and safety.

- Overview of industry standards (ISO, IPC, SAE) related to wiring harnesses.

- Understanding certification processes and requirements.

- Best practices for compliance and documentation.

- Common issues in wiring harnesses and their causes.

- Troubleshooting techniques and diagnostic tools.

- Maintenance practices for ensuring long-term reliability.

Our Hiring Clients

Career Opportunities

- Wiring Harness Design Engineer

- Manufacturing Engineer

- Quality Control Engineer

- Electrical Engineer

- Field Service Technician

Online Electrical Wiring Harness Course

The Online Electrical Wiring Harness Course at Caddesk Bangalore is an ideal learning program for individuals looking to develop expertise in the design, analysis, and management of electrical wiring harness systems. This course is tailored for students and professionals who prefer the flexibility of online learning while still gaining in-depth knowledge and practical skills in electrical wiring harness design. The online course offers a structured curriculum that covers the essential components of wiring harnesses, such as connectors, terminals, wires, and insulation materials, along with the principles of designing wiring systems for a variety of applications. Through a combination of detailed video lectures, interactive modules, and hands-on exercises, students will learn how to design, validate, and optimize wiring harnesses for industries like automotive, aerospace, and industrial systems. Key topics covered in the Online Electrical Wiring Harness Course include circuit layout, schematic creation, material selection, and manufacturing processes. Students will also be introduced to industry-standard design tools and software, which are integral for the development of wiring systems. By completing various practical assignments, students will gain experience in using CAD (Computer-Aided Design) tools to create detailed wiring harness designs and documentation. One of the key benefits of the online format is the flexibility it provides. Students can learn at their own pace and on their own schedule, making it easier for working professionals to balance their career and education. Additionally, the course offers access to expert instructors who provide personalized support, ensuring students can clarify doubts and receive guidance throughout the course. Upon completion of the Online Electrical Wiring Harness Course at Caddesk Bangalore, students will receive certification, equipping them with the skills and knowledge needed to excel in the field of wiring harness design and management. The course is perfect for those aiming to enter or advance in industries such as automotive engineering, electrical design, or aerospace, where the design and integration of wiring systems play a crucial role in product functionality and safety. Best Electrical Wiring Harness course in Bangalore.

Why Caddesk Bangalore Is Best Electrical Wiring Harness Course:

Caddesk Bangalore is the best choice for the Electrical Wiring Harness Course due to its industry-focused curriculum, hands-on training approach, and experienced instructors. The course is designed to provide students with comprehensive knowledge and practical skills needed to excel in the field of electrical wiring harness design, which is a critical component in industries such as automotive, aerospace, and industrial manufacturing. Caddesk Bangalore stands out as a top Electrical Wiring Harness training center in Bangalore for several reasons. First, the course is tailored to meet the latest industry standards and includes in-depth training on design, testing, and validation of wiring harness systems. Students will not only learn theoretical concepts but also gain practical experience using industry-standard software and tools, which are integral in the design process. The inclusion of real-world case studies and hands-on exercises ensures that students can apply their knowledge to actual projects and scenarios. Another advantage of choosing Caddesk Bangalore is the flexibility offered through both offline and online training options. This makes it possible for students from different locations or with busy schedules to benefit from the same high-quality education. The online Electrical Wiring Harness course allows students to learn at their own pace while still receiving personalized guidance from instructors. The offline mode, on the other hand, provides students with a more traditional, in-person learning experience. The course instructors at Caddesk Bangalore are industry experts with years of experience in electrical wiring harness design and management. They offer valuable insights and tips that can help students stay ahead in the competitive job market. The combination of expert-led training, flexible learning options, and the practical focus of the curriculum makes Caddesk Bangalore the best option for those looking to pursue a career in wiring harness design. In addition, students who complete the course receive ISO certification, which is a globally recognized qualification that adds credibility to their skills and enhances their job prospects. This certification ensures that the knowledge gained during the course meets industry standards and can be applied effectively in professional environments. Caddesk Bangalore is the best place to pursue an Electrical Wiring Harness course because of its experienced instructors, industry-relevant training, flexibility, and certification that open up numerous career opportunities in wiring harness design and management. Best Electrical Wiring Harness course in Bangalore.

Course Highlights

- Expert Trainers

- ISO Certification

- Industry Course Content

- Reference Guides

- Practice Materials

- Career Guidance

- Student login

- 100% Interviews

- Placement Training

What Our Student Says

One of the best Institute for cadd training in banglore with friendly staff and good assistance is provided by manohar sir in placements

I have learn autocad course from CADDESK Marathahalli ' Good faculty nice institute There support to job also

It was a good experience in caddesk institute, the faculty is good and the teaching is good , it is must recommended training institute for architecture, interior, and engineering students

FREQUENTLY ASKED QUESTION

Regular maintenance includes inspections, cleaning, and replacing worn-out components to ensure optimal performance and longevity.

Yes, wiring harnesses can be customized to meet specific application requirements, including custom connectors, terminals, and protective sheathing.

Wiring harnesses play a crucial role in vehicle performance by ensuring reliable electrical connections between various components.

They support critical functions such as engine management, lighting, infotainment systems, and safety features,

contributing to the overall efficiency and reliability of the vehicle.

Advancements in wiring harness technology include the use of lighter materials, improved insulation techniques and the integration of advanced diagnostic and monitoring features.

These innovations enhance performance, durability, and ease of maintenance.